06

2024

-

06

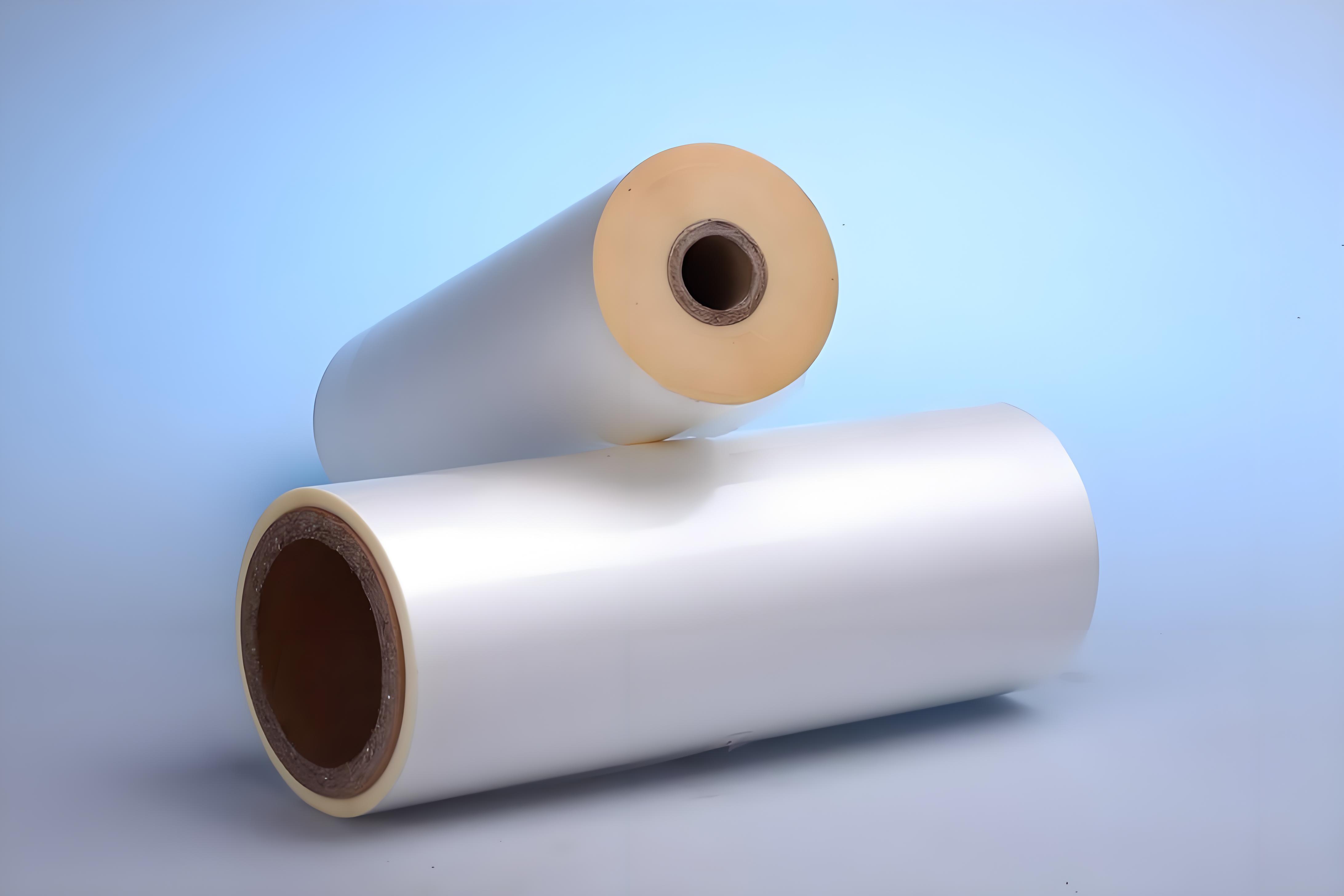

Product Introduction - BOPP Pre-coated Film

Author:

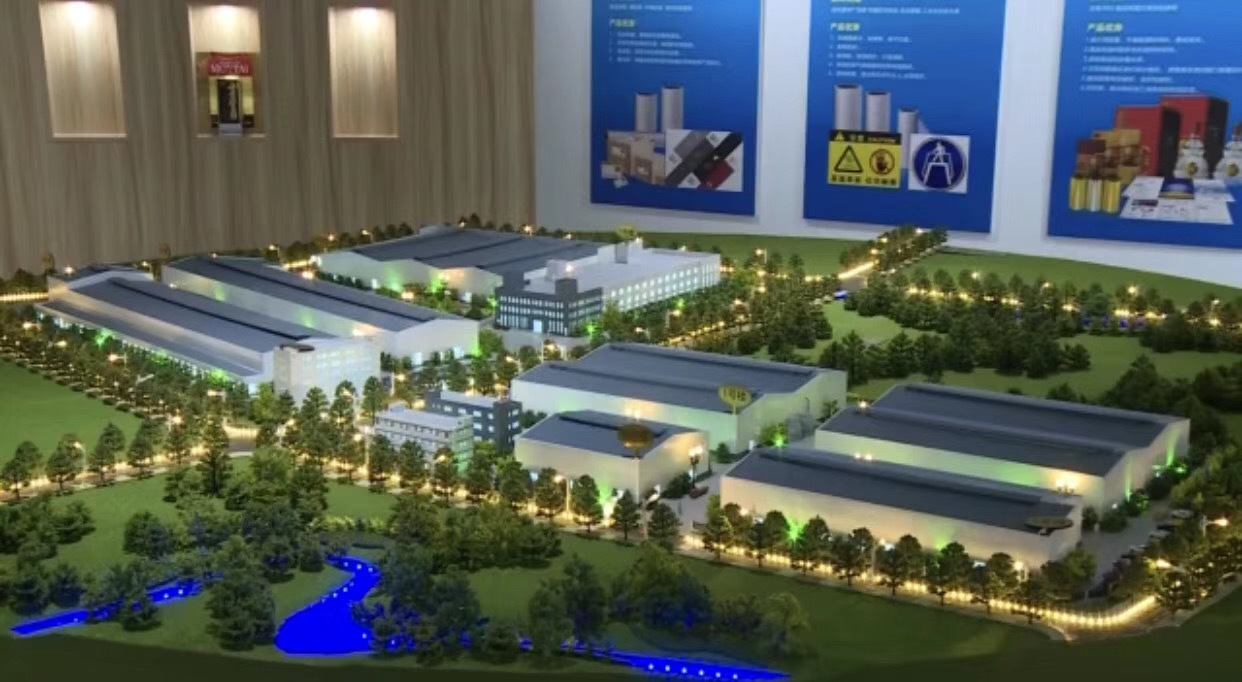

Chinafilm Group

Product Introduction - BOPP Pre-coated Film

BOPP pre-coated film is a high-performance film material made from biaxially oriented polypropylene (BOPP) as the substrate, with a special hot melt adhesive layer coated on the surface. It has a wide range of applications in the printing and packaging industry and has become a popular choice in the market due to its environmental friendliness, excellent performance, and high cost-effectiveness.

I. Product Advantages

1. Environmental Friendliness

Solvent-free, does not release volatile organic compounds (VOCs) during use, complies with international environmental standards, recyclable after disposal, and some products are biodegradable, meeting modern environmental protection needs.

2. High Transparency and Gloss

It has extremely high light transmittance and gloss, significantly enhancing the visual effect of printed materials, increasing color saturation and detail clarity.

3. Superior Physical Properties

High tensile strength, tear resistance, and abrasion resistance make it outstanding in protecting printed materials and packaging.

The surface hardness is high, with scratch resistance and fold resistance, ensuring long-term use without damage.

4. Easy Processability

The coated hot melt adhesive layer melts quickly at low temperatures, with excellent adhesion performance, suitable for various laminating machines.

Adapts to various printing materials, including coated paper and white cardboard, and is not prone to warping or delamination after lamination.

5. Waterproof and Stain-resistant

The surface has excellent waterproof and moisture-proof capabilities, effectively protecting printed materials and packaging from moisture and stains.

II. Product Features

1. Lightweight

BOPP film has a density of only 0.91g/cm3, making it one of the lightest plastic films on the market, which not only facilitates transportation but also reduces the total weight of packaging materials.

2. High Compatibility

Suitable for various lamination processes, including thermal lamination and cold lamination, widely compatible with different types of printing equipment and packaging needs.

3. Surface Treatment

Can provide various surface effects, such as gloss, matte, tactile, scratch-resistant, anti-fog, metallized, and laser, to meet different market demands.

4. Chemical Resistance

Has high resistance to acidic and alkaline solutions and organic solvents, suitable for packaging chemical products and special application scenarios.

5. Food-grade Safety

Non-toxic and odorless, can be in direct contact with food, widely used in the food and beverage packaging field.

III. Technical Parameters

Substrate thickness 15μm - 30μm, common thickness is 20μm, customizable production.

Adhesive layer thickness 5μm - 15μm provides uniform and efficient hot melt bonding performance.

Tensile strength ≥120 MPa (longitudinal) provides high mechanical strength, suitable for mass processing.

Elongation at break 150%-200% (longitudinal) maintains flexibility under high-pressure conditions.

Gloss ≥95% (glossy film) gives printed materials a mirror-like gloss effect.

High-temperature resistance can withstand temperatures above 110℃, adapting to various processing techniques.

Moisture permeability <3g/m2/24 hours, excellent moisture-proof performance.

IV. Application Range

1. Lamination of Printed Materials

Book Covers: Enhances the gloss and tactile feel of the cover while increasing wear resistance and durability.

Promotional Brochures: Provides visual impact and extends the preservation time of brochures.

Posters and Business Cards: Increases a sense of luxury through lamination, preventing damage and stains during long-term use.

2. Packaging Field

Food Packaging: Due to its waterproof, moisture-proof, and non-toxic properties, it is widely used in bread bags, snack bags, instant food packaging, etc.

Pharmaceutical Packaging: Protects medicine labels and packaging boxes, ensuring information is clear and does not fade over time.

Luxury Packaging: Such as cosmetic boxes, gift boxes, etc., enhances brand image through special film materials (such as tactile film and metallized film).

3. Industrial Uses

Electronic Product Packaging: Protects electronic device packaging from moisture and static electricity.

Advertising Materials: Used for POP advertising, display racks, and signage, providing excellent visual effects and durability.

4. Special Functional Scenarios

Antibacterial Film: Popular in the medical and food industries, helps inhibit microbial growth.

Anti-fog Film: Used for frozen food and refrigerator packaging, prevents fogging on the surface affecting aesthetics.

Tactile Film: Provides a smooth touch for high-end printed materials and packaging, enhancing user experience.

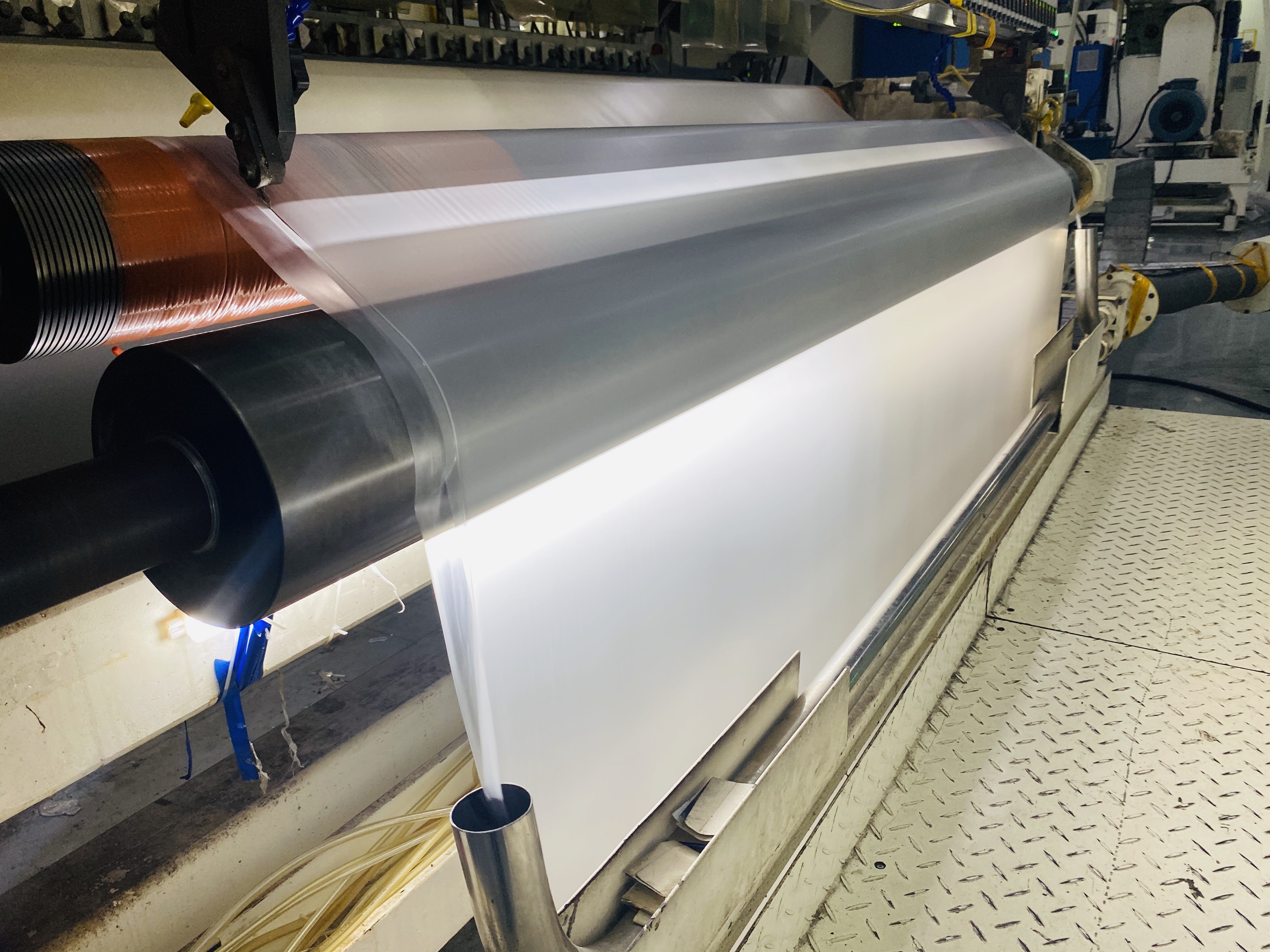

V. Production Process

1. Substrate Production

BOPP film is made through a biaxial stretching process, with a smooth surface and high transparency.

2. Hot Melt Adhesive Coating

A layer of hot melt adhesive is evenly coated on the film surface, with thickness adjustable according to requirements.

3. Composite Forming

At high temperatures, the hot melt adhesive strongly bonds with the substrate surface, forming a uniform composite film.

4. Roll Material Processing

Cutting the composite film into standard size rolls using high-precision cutting equipment for subsequent processing.

6. Market Competitive Advantages

1. Cost Effectiveness

Compared to traditional wet coating films, pre-coated films reduce equipment investment and energy consumption, resulting in lower overall costs.

2. Adaptation to Global Markets

BOPP pre-coated films have been widely adopted globally, meeting environmental regulations and market demands with their eco-friendliness and high performance.

3. Product Innovation

Multi-functional pre-coated films (such as scratch-resistant, anti-fog, antibacterial, etc.) provide enterprises with differentiated competitive advantages.

7. Future Development Directions

1. Eco-friendly Products

Accelerate the development of biodegradable pre-coated films to align with global sustainable development trends.

2. High Value-added Products

Increase the market share of touch films, metallized films, and special function films to provide more attractive options for the high-end market.

3. Technological Innovation

Further enhance the comprehensive performance of pre-coated films through the research and development of new hot melt adhesives and multi-layer composite structures.

4. Emerging Market Expansion

Expand into emerging markets such as Asia-Pacific, Africa, and South America to meet their rapidly growing packaging needs.

BOPP pre-coated films have become an indispensable material in the printing and packaging industry due to their excellent performance, wide application fields, and green environmental characteristics. With technological advancements and the continuous expansion of market demand, BOPP pre-coated films will play an increasingly important role in future development.

Latest News

2025-05-30

Chinaflilm Group's 12.91MW distributed photovoltaic power generation project successfully connected to the grid

The 12.91MW distributed photovoltaic power generation project, started on April 16, was completed in just 43 days, demonstrating "sunshine speed." Installed on factory rooftops, the project will significantly reduce carbon emissions and help the group achieve its green energy transformation.

2025-05-29

Chinafilm Group's distributed photovoltaic power generation project successfully connected to the grid, promoting green transformation of production

On May 29, 2025, Chinafilm Group reached a significant milestone—its 12.91398MW distributed photovoltaic power generation project was officially connected to the grid. The successful implementation of this project not only brought economic benefits to the company but also substantially benefited the power supply for production in its various projects.

2025-05-22

Application of scratch-resistant pre-coated films

Application of scratch-resistant pre-coated films

2025-04-15

Chinafilm Group's 12.91MW distributed photovoltaic project officially starts!

On April 15, 2025, Chongqing Chinafilm Technology Group Co., Ltd. (hereinafter referred to as "Chinafilm Group") and Sunshine New Energy Company jointly held a groundbreaking ceremony for a 12.91MW distributed photovoltaic power generation project in Chongqing. This marks the official launch of Chinafilm Group's important layout in the field of green energy and demonstrates the company's firm determination in sustainable development.

2025-04-14

The "Hardcore" Technology of Special Films: An In-depth Analysis of the Core Processes of High-Performance Film Materials

In modern industrial systems, thin-film materials have evolved from their traditional role of simple packaging into an advanced material system integrating functionality, structure, and intelligence. Special films, as the "high-end players" in the film family, are not only making great contributions in fields such as food, medicine, electronics, and automobiles, but also playing an irreplaceable role in the revolution of new material technologies.